Automatic Power Factor

Correction Systems

FEATURE: Enclosure is rigid design, bolted

construction with floor; economical in size.

Function: Accommodates multiple trays of kVAR;

provides for modularity and enclosure expansion;

allows for maximum kVAR in a small footprint;

compatible with match & line to switchgear and

motor control centers.

FEATURE: Enclosure uses a powder coat finish

painted light gray, includes 4-point latch, mechanism

and locking handle.

Function: Many years of superior protection and

durability of fabricated metal, hinges/hardware are

rust resistant for long life; optimum personnel safety.

FEATURE: Designed for convection or forced air

ventilation.

Function: Allows for proper heat dissipation of

components, extending life and maintaining the

integrity of operation.

FEATURE: Enclosure offers front, rear and both side

access.

Function: Provides several alternatives for service

personnel while still allowing equipment to be

located near or adjacent to a wall.

FEATURE: Top or bottom rear entry feed.

Function: Open access for easier installation of

equipment.

FEATURE: Complete assembly is UL and c-UL listed.

All components are UL listed/recognized or CSA

approved.

Function: Assures safety requirements met by

third party agency for complete assembly, not just

individual components.

FEATURE: Design of internal trays includes all major

components.

Function: One design with electrical and mechanical

devices mounted and wired simplifi es equipment

construction and testing continuity; allows for

modularity.

FEATURE: Design of internal tray accommodates

multiple kvar ratings and allows for tray expansion.

Standard “step� sizes are 25 kVAR, 50 kVAR, 100 kVAR

and 200 kVAR (480 VAC example).

Function: Standardization of trays provides greater

user selection to match switched kVAR needs today

and in the future.

StacoVAR equipment is designed and built to bring

you the highest quality product at the lowest price

possible. Our personal attention to the design and

assembly of each unit gives you powerful benefits

and a long list of standard and optional features that is unmatched in the industry.

Single unit enclosure (480 VAC)

accommodates up to 800 kVAR

or 600 kVAR with a molded-case

circuit breaker. When equipped

with reactors, 400 and 300

kVAR (C/B) are available. Single

unit enclosure’s approximate

dimensions are 83"H x 32"W x

24"D (with lifting eyes removed).

FEATURE: Multiple trays off er large total kVAR rating

in one enclosure.

Function: Reduces cost and floor space.

FEATURE: Bottom of trays include a unique venting

structure; trays are galvanized steel.

Function: Tray ventilation assures proper convection

flow, reducing potential for hot spots within enclosure;

improves overall cooling; galvanized steel for added

durability and resistance to environmental elements.

FEATURE: Clearance between trays allows for heat

dissipation and easy replacement.

Function: Little heat build-up allows the cooler

operating capacitors to have a longer life; should a

capacitor need replacement (damage from lighting or

other electrical fault), the unit can be easily replaced.

FEATURE: Tray to tray wiring is simple and neatly

configured. Bus bar is center mounted, bus links can

be easily removed/added should front servicing be

required, or another tray added.

Function: Helps service personnel locate connections,

reduces electrical stress, and makes trouble-shooting

or tray equipment additions easier.

FEATURE: All trays use a grommet where “through

wiring points� are located.

Function: Grommet protects wiring from any sharp

metal edges.

​FEATURE: Control wiring with numbered terminations

and quick connect plugs, when multiple enclosures

are used.

Function: Simplifies servicing.

FEATURE: Bus bar is electrical grade copper, Brite®

Nickel Plated and braced for 50k amps.

Function: Provides for best conductivity versus

aluminum, or non-plated type material; maintains

mechanical integrity should a major electrical fault

occur. Bus bar is not insulated, to help with visual

safety. Bus bar size is ½" x 2 ½" (480 VAC example).

FEATURE: Heavy Duty capacitors are polypropylene

type, three phase with discharge resistors and

overpressure safety device.

Function: Capacitors can operate in more

stringent conditions eff ectively with the dense resin

encapsulation, self-healing, metallized fi lm, which

provides for a dry (no free liquid) system. Capacitors

accommodate up to a 10% THD environment and

have a five year warranty.

FEATURE: Contactors are high duty, designed for

capacitor switching and include damping resistors.

Function: Specifi cally designed for high on/off

operation, helps reduce high currents from back-toback

switching of capacitors and extends life.

FEATURE: Contactors are same size for all part

numbers with “like steps.�

Function: Assures best switching values; spare parts

are more uniform, easier to obtain.

FEATURE: Fuses are rated for

200 kaic, 700 VAC, high overload

capability design, reacts quickly

to short-circuit conditions; fuse

ampere sizes are the same for “like�

kVAR steps.

Function: Maximum equipment

protection; spare parts are more uniform, easier

to obtain.

FEATURE: Fuses include individual blown fuse

indication, plus available indication lights (each phase)

on enclosure front door.

Function: Helps to quickly identify and replace specifi c

fuse.

FEATURE: Location of relays and CPT (CPT has primary

and secondary fuses).

Function: Allows for internal control devices to operate

and be functionally tested at the factory; ease of

serviceability; additional personnel safety.

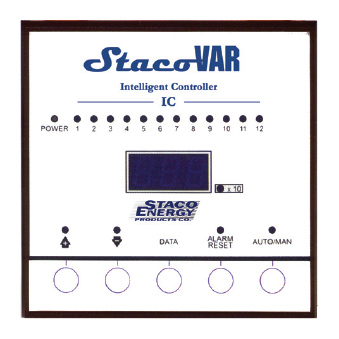

FEATURE: Standard 12-step StacoVAR Intelligent Power

Factor Controller has a front panel display with multiple

programmable functions and alarm.

Function: Provides for accurate regulation and control

of needed kVAR; all information is contained in one

location; easy to use.

FEATURE: PF controller is automatically disabled when

system overvoltage condition exists.

Function: Additional personnel safety.

FEATURE: Removable lifting eyes (top) included with

enclosure.

Function: Makes handling/installation simpler.

FEATURE: Optional molded case circuit breaker (C/B),

CT (split-core type, multi-tap), and TVSS.

Function: Breaker allows for a disconnection means

at the equipment location, and includes integral

plexiglass safety cover. CT is not required to be

purchased from a second source, and allows for a “one

size fi ts all.� TVSS enhances equipment protection from

surges.

FEATURE: Other power factor and harmonic

correction technologies available.

Function: Certain requirements or more complicated

applications can be met with the use of thyristor

switching, dynamic compensation/real time power

factor correction, or by employing active (power

electronic) harmonic fi lters.

Automatic Power Factor Correction

(De-Tuned) with Reactors

(All the features listed above, plus the following)

FEATURE: Tray design includes a barrier between

capacitors and reactors.

Function: Reduces heating between components;

helps improve expected life.

FEATURE: Enclosure includes fan package.

Function: Forced air cooling improves movement

of ambient air, helping to cool components.

FEATURE: Three phase iron core reactors, copper

wound, UL recognized, designed for 3.78 (well under

the 5th order at 227Hz).

Function: Built for long life, sized to accommodate

higher than normal currents to protect capacitors while

providing mitigation.

FEATURE: Iron core reactors include a thermal switch.

Function: Provides automatic shut-down when reactor

overheats to maintain the integrity of components

while still allowing the system to partially operate.

FEATURE: Heavy duty capacitors used with reactors

are rated for 690 VAC (480 VAC system), 480 VAC (240 VAC

system).

Function: Harmonic environments generally produce

high currents, which may damage or reduce the life of

the capacitor. 690 VAC rated capacitors help mitigate

these concerns with a higher level of performance.

Controller Front Panel

.......................................................................................................................................................................................................................................